05. September 2022

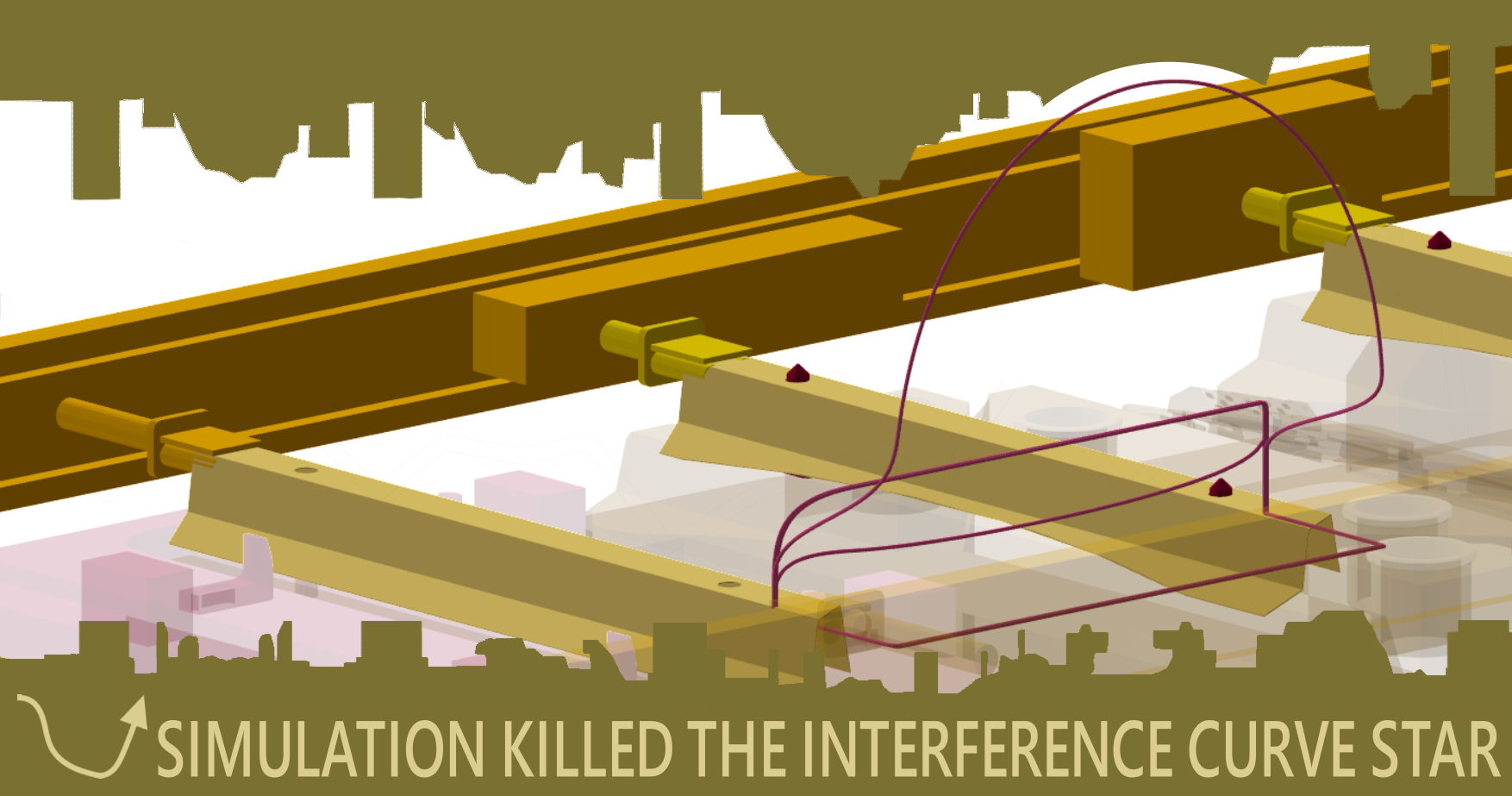

Stamping equipment is characterized by its adjustability. The motions of the system are adjustable and enable the productivity to be optimized significantly. Therefore, it is obvious to use the CAD systems features to emulate the throughput to take advantage of such benefits. The additional gain as well as the effort of such an animation hardly justify the result. A real simulation using press parameters and exact stroke rate calculation is easier to use, faster and finally cheaper.

10. Mai 2022

AI and machine learning are considered to be ultimate weapons in the handling of large and small challenges. Algorithms process incredible amounts of data and, despite monotonous and repetitive routines, neither feel bored nor lose concentration. Away from the discussion about the possibilities and limits of this, however, humans gain two things. A different way of looking at problems, as well as time for creative solutions. This is the breeding ground for innovation and competitive advantage.

22. Juli 2021

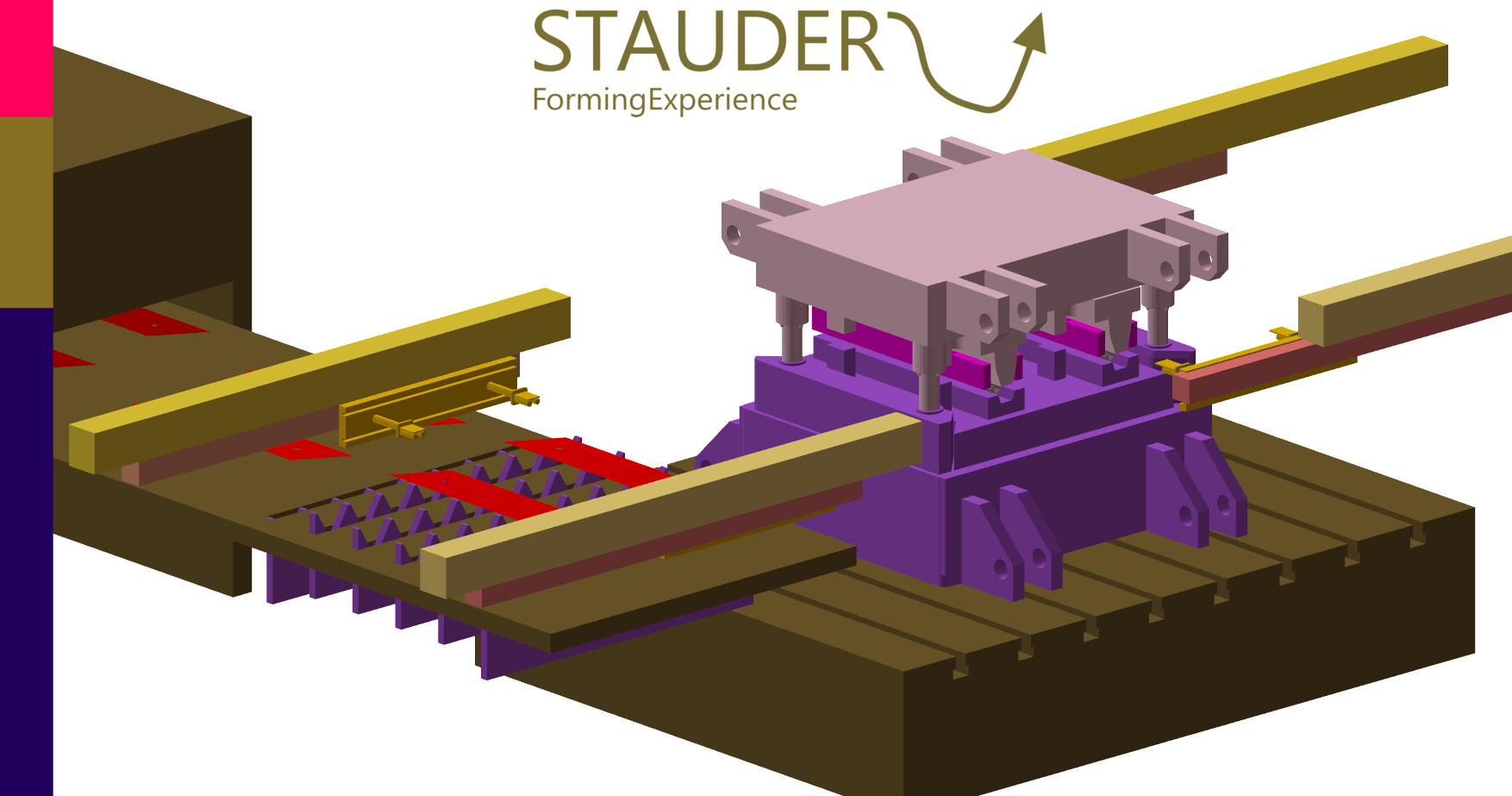

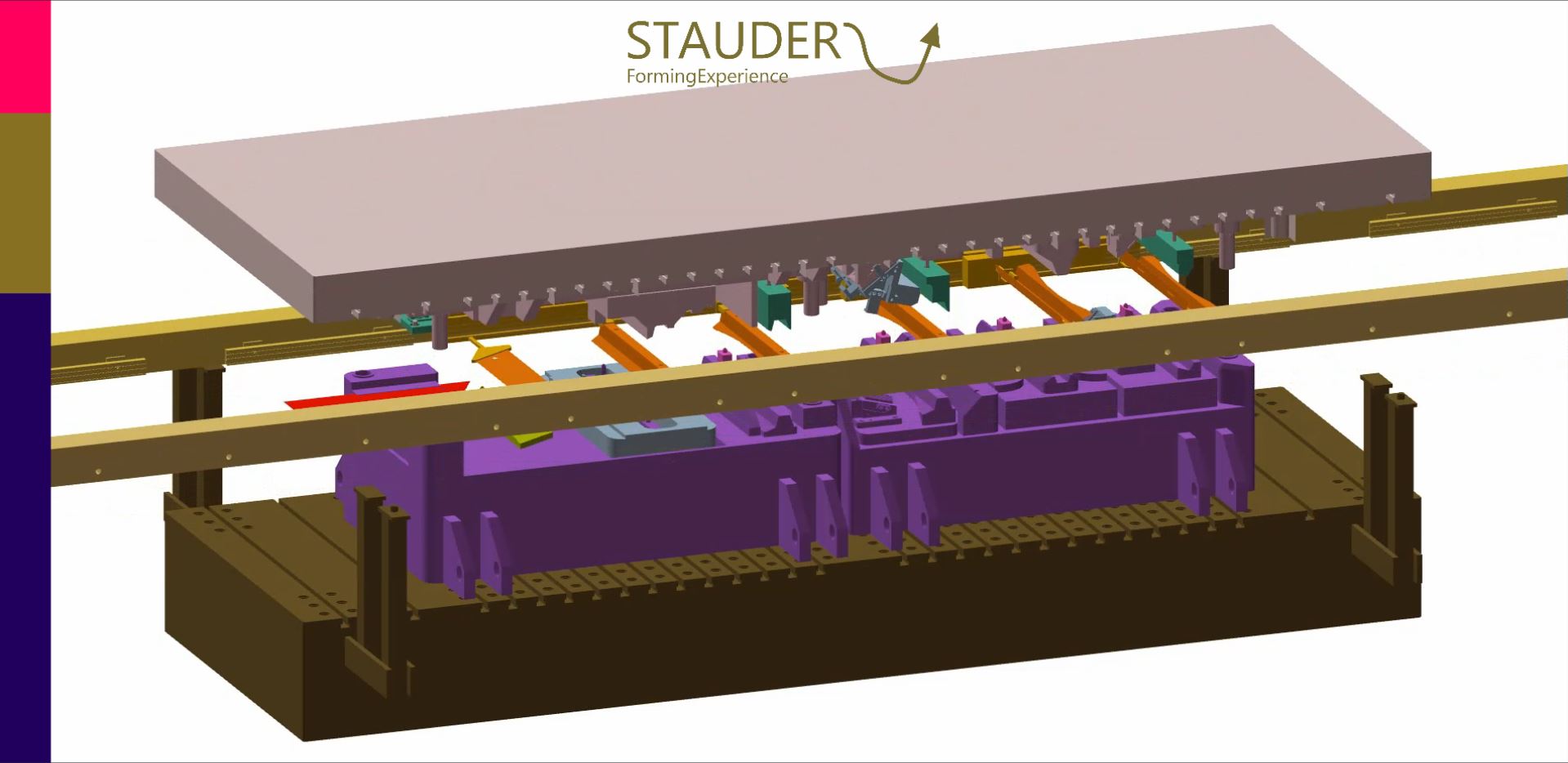

The use of kinematic simulation in the metal forming creates a better understanding of the processes in and on press through visualization. The great advantage is that the entire process can be tested offline and in advance of the existence of real machine or die.

To increase productivity on hot forming equipment, it is not enough to optimize the part transportation within the die clamping area. The entire part transfer process including the heating and feeding process must be simulated.

13. Mai 2021

One of the principles that drives me is "Simplicity is the soul of efficiency".

This sums up what kinematic virtual simulation of press and die movements is for. This 3D CAD data-based methodology is the key to accelerate die design times and minimize machine downtime. But best of all, the combined view of die design in the context of machine movements makes the potential output rate predictable and thus the design optimizable.