obviCALC® – Efficiency starts with understanding

With obviCALC® you can optimize transfer movements faster, safer and smarter - right from the planning phase, but also beyond - directly on the press line. The software calculates stroke rates precisely in advance and supports you in putting new tools into operation quickly and smoothly.

Thanks to its intuitive user interface and targeted functions, obviCALC is the ideal tool for designers, planners and setters who want to save time and reduce risks.

Motion sequences can be easily analyzed, bottlenecks identified at an early stage and optimum cycle times defined - without the need for time-consuming real-life tests.

Your benefits at a glance:

- Significantly shorter set-up times for new or relocated tools

- Early stage, automatic collision detection

- Optimized transfer movements for maximum productivity

- Stroke rate calculation and optimization using spaceASSIST

obviCALC® brings clarity, speed and security to your process - so that every new or relocated tool delivers what you expect right from the start: efficiency in mass production.

In addition to the press manufacturer-independent architecture, the software offers the advantage of being able to cover a wide variety of press line types. The input of press-specific data and its calculation is based on a structure file. This reflects the components and functionality of the press line.

Thus you acquire the license for a software that can cover both 3-axis transfer presses with one or more slides or, for example, systems for hot forming with a feeder and several transfer units or even press lines with crossbar feeder.

Not only does this reduce the cost of licenses, it also means that only one software for throughput optimization needs to be mastered.

Below you will find an overview of the functions of obviCALC. Once you have become curious, I would like to invite you to a personal online demo. Feel free to write to me using the contact form - I will be happy to show you and your team how you can work more efficiently and goal-oriented with obviCALC.

Benefits:

- Independent definition of new machines: curves, limits and/or machine-specific algorithms can be read in, entered or selected by the user in a machine definition interface.

- Calculation of press and 3-axis transfer movements in crank angle or mm specification or import of a manufacturer-independent ram curve defined by the user.

- Updates and bug fixes during the license period

- E-mail and telephone support

With us, you benefit from more than just software applications: STAUDER FormingExperience GmbH not only provides you with powerful tools, but also a holistic partner at your side. Our aim is to provide you with comprehensive support on your way to greater productivity and efficiency in the press shop. Whether during your engineering projects, during realization of specific optimization measures or directly at the press: We support you from analysis to implementation - for example in setting up optimized stamping motions or providing targeted training for your employees.

Our goal: measurable improvements, sustainable knowledge transfer and smooth processes along the entire process chain.

ovviCALC® Features

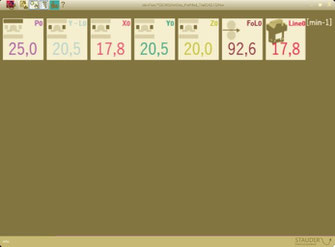

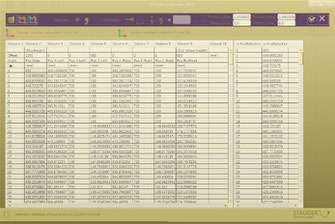

Optimized Motions

The flexible and intuitive interface enables the calculation and optimization of stroke rate and clearance-relevant system parameters.

Its system-oriented, modular design ensures future-proofing and adaptability to a wide range of equipment and automation concepts.

Modular Software

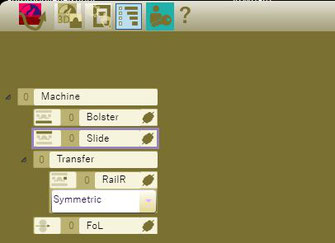

Whether it's a classic 3-axis transfer press with a single press, as shown in the example on the right, or a hotforming line with one press, two 2-axis transfer feeders, and automated feeding systems — the flexible software architecture enables you to simulate a wide range of system configurations and automation concepts with ease.

Multiple simulation scenarios

Support your decisions with verifiable cost data. Based on an OEE forecast—which takes availability, strokes per minute, and quality factors into account—you can identify the most profitable alternative. This tool provides the flexibility to evaluate a wide range of investments, including equipment, tooling, or production technologies, and to calculate the return on investment (ROI) with confidence.

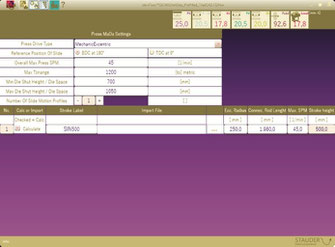

Customizable Maschine Data

Machine parameters relevant to stroke rate and clearance can be defined for each component of the press-line contained in the tree structure. Access to this data can be blocked via a password defined by the user and thus protected against unwanted manipulation.

Stroke Rate Calculation

Based on the parameters entered, the achievable number of strokes is calculated and output for each individual system in the line structure. This allows the productivity-limiting system component to be specifically optimized for a higher output rate.

Slide Motion

Depending on the mechanical press drive type selected in the machine data - eccentric, eccentric with slide stroke adjustment or servo - either a fixed or several predefined slide kinematics can be selected. For servo presses, it is also possible to read in slide curves from text files.

Transfer Set-Up

Standard definition of transfer movements by positions and angle according to the press HMI. Machine limits are stored and exceeding the minimum/maximum travel distances is signalized. In addition to the classic 3-axis sequence, any special operating modes such as vacuum operation or 2-axis operation can be set. The current setup is displayed directly in the circular chart, making it easier to define and optimize movements.

Transfer optimization with spaceASSIST

Revolutionarily simple is the ability to define movements in 3D with 100% precision using simlply to understand millimeter input. The smart software automatically calculates optimized angle

values, saving time and delivering optimal transfer parameters in just moments.

Vibrations of each individual axis can be specifically impoved via acceleration settings. Overlapping motions can be predefined within the process-relevant movement, and other transfer modes are handled with the same intuitive logic – all within a fully controllable 3D environment.

Coil feeder FoL

For coil feeding systems, feed parameters such as feed length and start-stop angles can be defined to precisely control timing. As part of a comprehensive frontloading approach for determining all motion-relevant parameters, cam values for intermediate opening of the feed rolls as well as the strip entry height can also be specified.

Import of slide motions

A high level of flexibility is provided by the import functionality for ram kinematics. Curve files from a wide range of manufacturers can be used directly in the software without any modifications or additional effort.

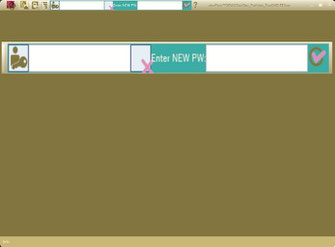

User level

By setting a user-defined password, changes to machine data can be restricted and made accessible only to authorized users. This effectively prevents unintended modifications to system parameters.

File-based operation

The software does not require operation within a virtual operating system, nor does it rely on external databases for data management. As usual, machine and project data can be stored within a user-defined folder structure on a local drive or network location. All data – including motion and 3D information – is saved in a single, unified file using the “*.FEflow” format, eliminating the need for separate file types.

Flexible Licensing

With our flexible licensing models, you can tailor the use of obvi software precisely to your specific requirements. You define not only the duration of the license but also where and how it is used: within your organization, across teams via a network license, or even outside your company – for example, in collaboration with customers, development partners, or while working remotely with a portable node-locked or floating license.

This approach allows you to optimize licensing costs through shared usage within your own network while simultaneously opening up new opportunities for collaboration. Use obviCALC, obviFLOW, or obviFORCE to present your design concepts clearly and visually – whether internally or to clients.

Your benefit: maximum flexibility, minimal cost, and a powerful boost to communication and efficiency – fully aligned with our mission to provide you with tools that truly make a difference.

Requirements

Operating system:

- Microsoft® Windows® 10 (64 Bit)

- Microsoft® Windows® 11 (64 Bit)

- Microsoft Framework 4.7.2 installed

CPU:

- min. 2,8 GHZ, 4 Cores

RAM:

- 4GB min.

HD:

- 200 MB min. - for installation, SSD recommended

Grafics:

-

1GB GPU,

resolution min 1920x1080 - Touch operation supported

Rights:

- Admin rights during installation

- USB-Slot

- Installation license server und licence tools management software

- Read-/ Write Acces on user directories