obviFLOW® – Virtual simplicity for real efficiency.

With obviFLOW®, you bring motion into your planning—in the truest sense of the word. The app simulates the kinematic sequences of your forming processes directly based on 3D data—either using the movement parameters optimized in obviCALC or freely defined via imported motion tables.

What makes it special: obviFLOW® operates as a standalone application and automatically checks your tool designs for collisions, clearances, and obstacles—quickly, precisely, and visually.

Complex motion sequences become clearly understandable and can be optimized early on —

in line with obvi’s philosophy: making the obvious visible before it becomes expensive.

Your benefits at a glance:

- CAD-neutral and intuitive to use

- Automatic collision detection and visual analysis

- Optimization of clearance and motion quality: simulate any number of special movements, e.g., pneumatic actuators

- Simulation of sliders, sheet metal, and hold-down movements

- Easy import of existing 3D CAD data, regardless of whether designed at bottom dead center (BDC) or top dead center (TDC)

obviFLOW enables you to validate tool designs early and avoid costly iterations during production. For smooth workflows, reduced risks—and a tool that fits perfectly before its first use.

obviFLOW – because every movement counts.

Below is an overview of obviFLOW’s features. If you’re curious to learn more, I warmly invite you to a personal online demo. Just send me a message via the contact form—I’ll be happy to show you how you and your team can work more efficiently and purposefully with obviFLOW.

And if you’d like to experience obviFLOW directly on one of your own tools, we also offer simulation as a service. This way, you gain practical insights and see firsthand the tangible benefits obviFLOW can bring to your specific situation—without any need for your own installation. It’s the perfect way to uncover potential, support decision-making, and build internal consensus.

Your Benefits at a Glance:

- Flexible customization: Easily define your system environment yourself—CAD data for presses and equipment can be exchanged, and sensitive areas are protected by user-level access.

- Clear visualization of clearances: Bottlenecks and collisions are made visually obvious and can be specifically resolved.

- Improved team communication: Everyone involved in development and production sees the same processes and instantly understands the relationships—creating clarity and preventing misunderstandings.

- Intuitive operation: Even complex simulation scenarios can be handled effortlessly—no special expertise required.

- Always up to date: Benefit from regular updates and bug fixes throughout the license period.

- Direct support: Personal assistance via email or phone whenever you need it.

Benefit from more than just software: At STAUDER FormingExperience GmbH, you receive not only powerful tools but a comprehensive partner by your side. Our commitment is to support you fully on your journey toward greater productivity and efficiency in the press shop. Whether during your engineering projects, the implementation of targeted optimization measures, or directly at the press, we assist you from analysis through execution—such as setting up optimal forming curves or providing tailored training for your team.

Our goal: measurable improvements, sustainable knowledge transfer, and seamless processes throughout the entire value chain.

ovviFLOW® Features

Kinematic Press Simulation

The virtual simulation of press and transfer movements and the ability to add tool data in 3D enables the ideal and shortest tool design process.

Design errors are avoided and even the most complex tilting, twisting or pitch compensation operations can be mastered.

Pad and blank holder movements as well as slide movements can be simulated in the simplest way.

Modular Software

Whether a classic 3-axis system with one press, a system for hot forming with one press and two 2-axis transfer feeders and feed automation or a press line, as shown in the example on the right, the flexible software architecture makes it possible to simulate a wide variety of press configurations/models and automation concepts in one software tool.

Versatile simulation scenarios

CAD data of all relevant items can be imported flexibly and freely into the simulation. This not only creates the basis for a realistic representation of new press lines, but also offers you the opportunity to further evolve your digital twin together with the real machine.

Whether retrofits, modernizations or complex expansions - the virtual machine can always be kept up to date. This means you are not only simulating correctly, but also future-proof.

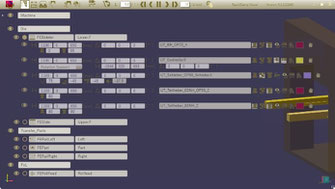

Specifications on the model

All geometry-related settings such as speical pneumatic movements, blank holder movements and offsets are made directly in the structure tree.

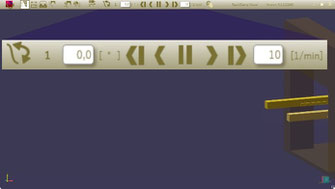

Simple to operate kinematics

Intuitive handling of the simulation without special knowledge. Press angles are displayed for the respective position or can be entered directly.

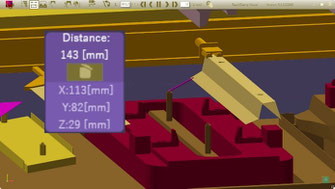

Dynamic measurements

Any number of measurements can be created between geometries. The measurement results are displayed as a total distance and with the respective axis values and are continuously updated depending on the current press angle.

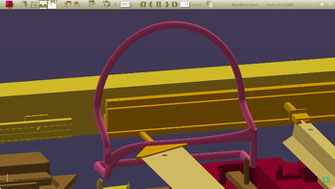

Intuitive Interference Curve placement

Any points of the displayed 3D data can be selected and the relevant and current interference curve is inserted correctly. As with measurements, the curves displayed are automatically updated when the movement changes. These can be exported in STL format for further use in the respective CAD software. This makes it possible to implement a continuous design process from the method to the finished tool with less effort.

Slices

A slicing plane can be created through all the 3D geometries shown. The section plane can be selected according to a selectable axis direction and can be moved by specifying the position. The section plane can also be retained in the simulation process. This means that curves can also be optimally set for details hidden by edges.

Special Motions

Special movements generated by pneumatic actuators in the tool or on the transfer can be defined directly within the software in any quantity and assigned to specific geometries.

Furthermore, tool movements in the z-direction (e.g., down- or blankholders, part lifters, or stabilizer movements) as well as cam-slider movements in the lower and upper tool can be simulated.

This enables even the most complex motion sequences to be quickly and easily evaluated and optimized for performance and clearance during the design phase.

Automatic collision detection

Automatic collision detection provides an additional level of safety and clarity for your simulations. Tools and machine components are systematically checked for possible collisions. Depending on your settings, the simulation is automatically stopped if a collision is detected and the affected, intersecting areas are clearly highlighted.

The software also allows you to check defined safety distances: This allows you to recognize at an early stage whether specified minimum clearance distances are being maintained to ensure the protection of your press line and tooling. This function also reliably identifies collisions that are difficult to see.

Flexible Licensing

With our flexible licensing models, you can tailor the use of obvi software precisely to your specific requirements. You define not only the duration of the license but also where and how it is used: within your organization, across teams via a network license, or even outside your company – for example, in collaboration with customers, development partners, or while working remotely with a portable node-locked or floating license.

This approach allows you to optimize licensing costs through shared usage within your own network while simultaneously opening up new opportunities for collaboration. Use obviCALC, obviFLOW, or obviFORCE to present your design concepts clearly and visually – whether internally or to clients.

Your benefit: maximum flexibility, minimal cost, and a powerful boost to communication and efficiency – fully aligned with our mission to provide you with tools that truly make a difference.

Requirements

Operating system:

- Microsoft® Windows® 10 (64 Bit)

- Microsoft® Windows® 11 (64 Bit)

- Microsoft Framework 4.7.2 installed

CPU:

- min. 2,8 GHZ, 4 Cores, more recommended

RAM:

- 4GB min.

- 16GB; 32 GB or more recommended

HD:

- 450 MB min. - for installation, SSD drive recommended

Grafics:

-

4GB GPU,

resolution min 1920x1080, 2 displays recommended - Compatiblitiy with 3Dconnexion Spacemouse

Rights:

- Admin rights during installation

- USB-Slot

- Installation license server and license software management tools

- Read-/Writeaccess to user directories