obviFORCE® – Forceful insights for the right decisions

obviFORCE® is a stand-alone tool for the rapid estimation of off-center forces and force build-up in multi-operation forming tools. Users can simply enter values such as forming forces or spring forces and select an approximated force profile from various forming processes or alternatively import force curves from forming simulations.

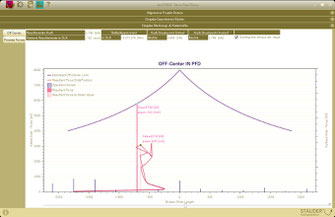

The tool then calculates the resulting forces acting on the press slide for each tool stage. These are graphically displayed both in the top dead center position (UT) and along the slide position.

- Stand-alone application for force analysis

- Rough force build-up or exact data from the simulation fully flexible input

- Visual representation of the force build-up to minimize cutting impacts and optimize eccentrically acting forces for minimal tilting

- Simple input for fast results - because time is short

With obviFORCE, you gain valuable insights into loads and force distributions at an early stage - laying the foundation for durable tools and safe processes.

obviFORCE - as each and every force counts.

Below you will find an overview of the functions of obviFORCE. If you are curious, I would like to invite you to a personal online demo. Simply send me a message using the contact form - I will be happy to show you how you and your team can work more efficiently and purposefully with obviFORCE.

And if you would like to experience obviFORCE directly on your own tool: We are happy to offer you a simulation as a service. This gives you practical insights and allows you to immediately see the specific added value that obviFORCE brings to your situation - without having to install it yourself. Ideal for uncovering potential, backing up decisions and convincing others internally.

Your benefits at a glance:

- Fast calculation of loads based on existing data from the method plan

- Quick results in the shortest possible time for fast decisions

- Optimized press selection - early profitability assessment based on the method plan

- Flexible layout adaptations - changes with minimal effort for efficient force reduction

- Software maintenance included - regular updates and bug fixes during the license period

- Reliable support - e-mail and telephone support

Benefit from more than just software: At STAUDER FormingExperience GmbH, you receive not only powerful tools but a comprehensive partner by your side. Our commitment is to support you fully on your journey toward greater productivity and efficiency in the press shop. Whether during your engineering projects, the implementation of targeted optimization measures, or directly at the press, we assist you from analysis through execution—such as setting up optimal forming curves or providing tailored training for your team.

Our goal: measurable improvements, sustainable knowledge transfer, and seamless processes throughout the entire value chain.

ovviFORCE® Features

Minimum data required

The basic data available from the method planning - in particular the number, position and forming force of each stage - is sufficient for determining the press load due to eccentric forces, the required working capacity and the force curve over the slide stroke. For greater accuracy, results from forming simulations can also be imported as text files. The flexible import function is vendor-independent and ensures seamless integration into existing planning and simulation processes.

Easy to use

The software is designed so that it can be used safely and efficiently even if it is only used occasionally.

Thanks to the intuitive interface and the direct calculation of results for each input, there is no need for a separate calculation run. Interdependencies are immediately understandable thanks to

graphical representations, which significantly simplifies analysis and optimization.

Evidence-based press selectionl

The selection of the right press is data-based and based on the parameters defined in the forming method. In this way, the presses available in the press shop that meet the forming process requirements can be specifically identified in the early planning phase. This well-founded pre-selection ensures that the tool can be reliably operated on the selected machine - and under economically optimal conditions. At the same time, the data-based evaluation also makes it easier to select suitable replacement systems or back-up strategies should the worst come to the worst.

All press manufacturers

The software is completely manufacturer-neutral and can therefore be used for presses of all makes. This allows you to use a standardized tool for the entire machine park - regardless of the age, type or manufacturer of the equipment. All press-specific parameters required for the calculation can be defined by the user. This creates maximum flexibility, ensures planning security and keeps all options open for future investments - without restrictions due to press-related manufacturer lock-in.

Reduced Snap-Through

Thanks to the advance insight into the force build-up over the stroke, potential shocks caused by snap-through can be identified as early as the planning phase. The software visualizes these load peaks / Reverse Tonnage clearly in diagrams with integrated evaluation functions. Critical points can thus be identified and effectively reduced through targeted measures - such as height adjustments or optimized cutting sequences. This protects the tool and press, increases process reliability and extends tool life.

Smaller tonage

By taking a detailed look at the distribution of forces over the entire bolster surface and how they change over time across the ram stroke, eccentric forces can be predicted much more precisely. In contrast to conventional analysis at the bottom dead center (BDC), which often leads to generous safety margins, the software enables a realistic evaluation of the actual load. This means that presses with a lower tonnage can often be used - without compromising process reliability or quality. In addition, tool-specific values for the required working capacity and the required nominal force before UT are clearly shown and are directly incorporated into the planning decision.

Flexible Licensing

With our flexible licensing models, you can tailor the use of obvi software precisely to your specific requirements. You define not only the duration of the license but also where and how it is used: within your organization, across teams via a network license, or even outside your company – for example, in collaboration with customers, development partners, or while working remotely with a portable node-locked or floating license.

This approach allows you to optimize licensing costs through shared usage within your own network while simultaneously opening up new opportunities for collaboration. Use obviCALC, obviFLOW, or obviFORCE to present your design concepts clearly and visually – whether internally or to clients.

Your benefit: maximum flexibility, minimal cost, and a powerful boost to communication and efficiency – fully aligned with our mission to provide you with tools that truly make a difference.

Requirements

Operating system:

- Microsoft® Windows® 10 (64 Bit)

- Microsoft® Windows® 11 (64 Bit)

- Microsoft Framework 4.7.2 installed

CPU:

- min. 2,8 GHZ, 4 Cores, more recommended

RAM:

- 2GB min.

HD:

- 200 MB min. - for installation, SSD drive recommended

Grafics:

-

4GB GPU,

resolution min 1920x1080

Rights:

- Admin rights during installation

- USB-Slot

- Installation license server and license software management tools

- Read-/Writeaccess to user directories