12. Mai 2022

Today, we all know that servo presses are the best in terms of stroke rate and output. But what can be done when the production time is plenty to cover the demand of parts and at the same time the cost of materials and energy make any previous calculation obsolete?

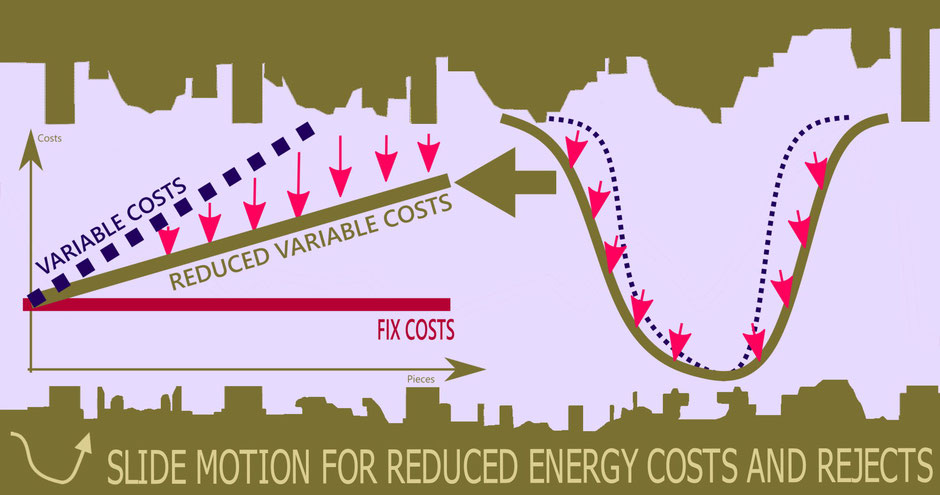

A slide curve adapted to current requirements significantly reduces variable costs. Instead of aiming for a high stroke rate, it is currently worthwhile to optimize the re-set-up in terms of reduced energy costs and fewer rejects.

05. April 2020

We are receiving dramatic pictures and messages these days.

But isolated glimmers of hope - as is currently the case at the petrol pumps - delight the consumer. And I am sure that just as the sun rises again after every night, we will overcome this crisis together.

Would you like to know how you can save on training in sheet metal forming?

Webinars for press setters provide basic knowledge for the optimal parameters of servo presses and/or for 3D / 3axis transfers.

25. März 2020

Social distancing? Low order volumes? What about the health of the loved ones? …?

A resource that is very rare in normal times - time - has been made available in the production environment.

Webinars offer an ideal opportunity to increase the knowledge of your employees while respecting the present ban on human contact. Use the time that has become free during these days without further interruptions in production, without affecting shift schedules to increase future productivity.

21. November 2019

Whether you want to prepare yourself for the challenges that industry 4.0 / IoT or e.g. as a reaction to electromobility brings, there are many reasons why you want to recruit experts for your company. Providing know-how and expertise in new business fields or niche areas is always a challenge.

We also encounter these challenges in our everyday lives, even beyond the above-mentioned trendy and visionary directions.

16. April 2019

Maximum stroke rates on presses are an obvious must in times of enormous demand, no question.

As soon as the demand for formed parts drops, it is more important to trim the production to maximum efficiency and thus to optimum stroke rates. Specifically, this means re-adjusting the press and 3-axis transfer settings not only in regard of the absolute number of strokes, but especially in terms of the reduction of maintenance and the energy consumption per manufactured part.