05. September 2022

Stamping equipment is characterized by its adjustability. The motions of the system are adjustable and enable the productivity to be optimized significantly. Therefore, it is obvious to use the CAD systems features to emulate the throughput to take advantage of such benefits. The additional gain as well as the effort of such an animation hardly justify the result. A real simulation using press parameters and exact stroke rate calculation is easier to use, faster and finally cheaper.

12. Mai 2022

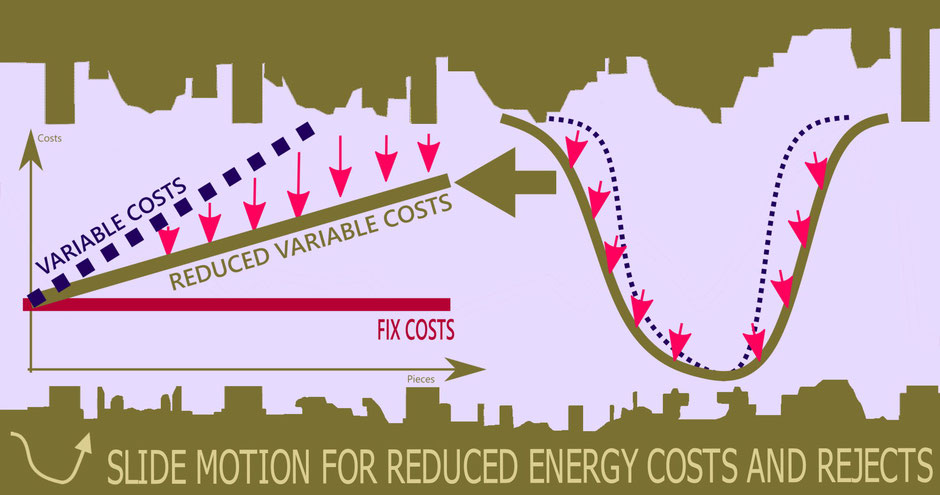

Today, we all know that servo presses are the best in terms of stroke rate and output. But what can be done when the production time is plenty to cover the demand of parts and at the same time the cost of materials and energy make any previous calculation obsolete?

A slide curve adapted to current requirements significantly reduces variable costs. Instead of aiming for a high stroke rate, it is currently worthwhile to optimize the re-set-up in terms of reduced energy costs and fewer rejects.

21. November 2019

Whether you want to prepare yourself for the challenges that industry 4.0 / IoT or e.g. as a reaction to electromobility brings, there are many reasons why you want to recruit experts for your company. Providing know-how and expertise in new business fields or niche areas is always a challenge.

We also encounter these challenges in our everyday lives, even beyond the above-mentioned trendy and visionary directions.

26. Oktober 2019

Great efforts are made to increase the production quantity of forming machines. Those responsible diligently create value stream analyzes, constantly optimize setting values, invest in modern production equipment and much more in order to increase output.

A concrete and outright structured analysis of the process bottleneck helps to address the causes with efficient means and leads to a sustainable improvement.

16. April 2019

Maximum stroke rates on presses are an obvious must in times of enormous demand, no question.

As soon as the demand for formed parts drops, it is more important to trim the production to maximum efficiency and thus to optimum stroke rates. Specifically, this means re-adjusting the press and 3-axis transfer settings not only in regard of the absolute number of strokes, but especially in terms of the reduction of maintenance and the energy consumption per manufactured part.

28. März 2019

One would think that the correct application of clearance curves in the transfer tool design is not only an absolute must, but a matter of course.

A technically error-free and clear flow chart, whether classical with clearance curves or carried out based on a virtual flow simulation, enables the press to be operated at maximum output.