10. Mai 2022

AI and machine learning are considered to be ultimate weapons in the handling of large and small challenges. Algorithms process incredible amounts of data and, despite monotonous and repetitive routines, neither feel bored nor lose concentration. Away from the discussion about the possibilities and limits of this, however, humans gain two things. A different way of looking at problems, as well as time for creative solutions. This is the breeding ground for innovation and competitive advantage.

22. Juli 2021

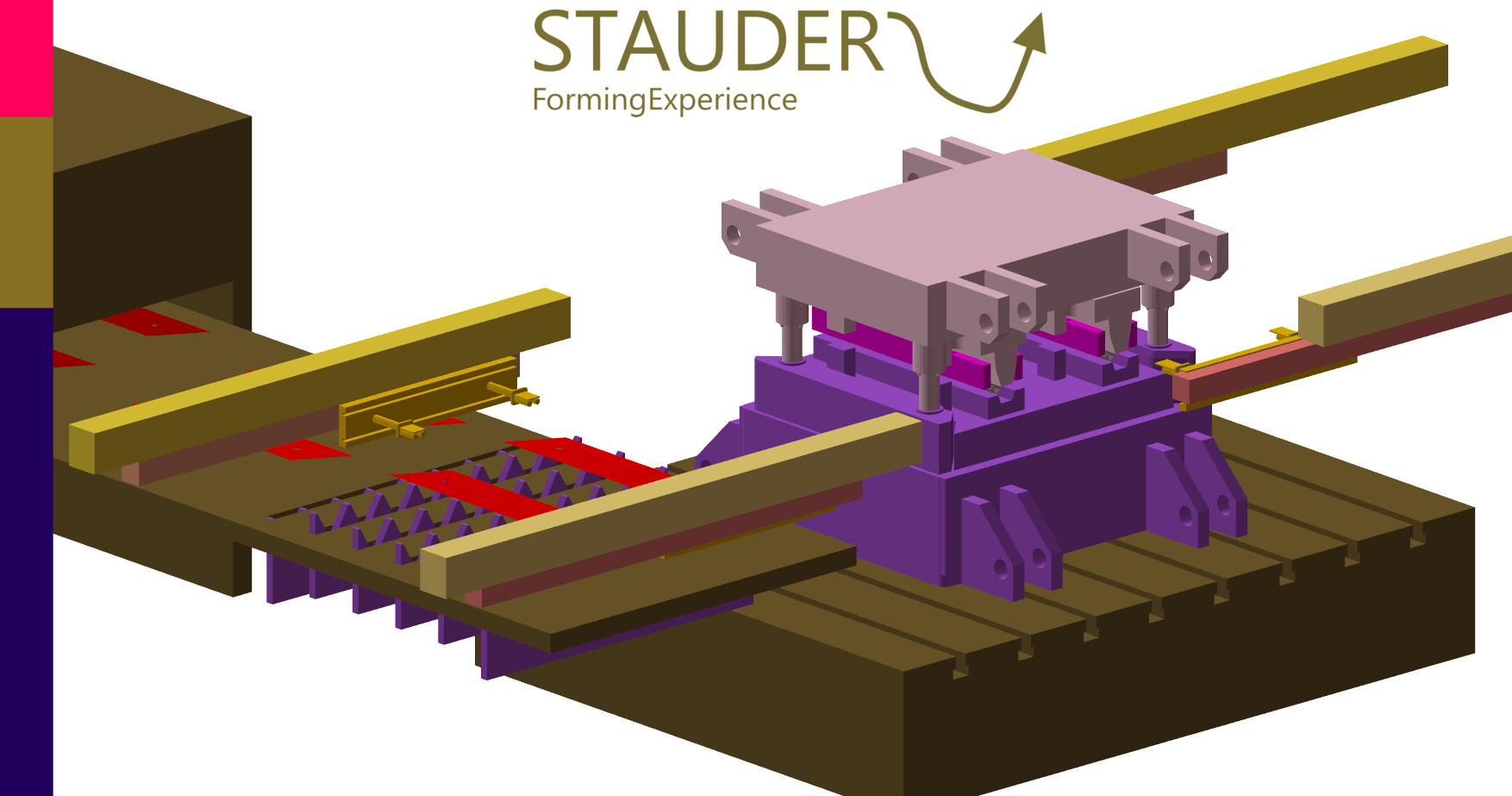

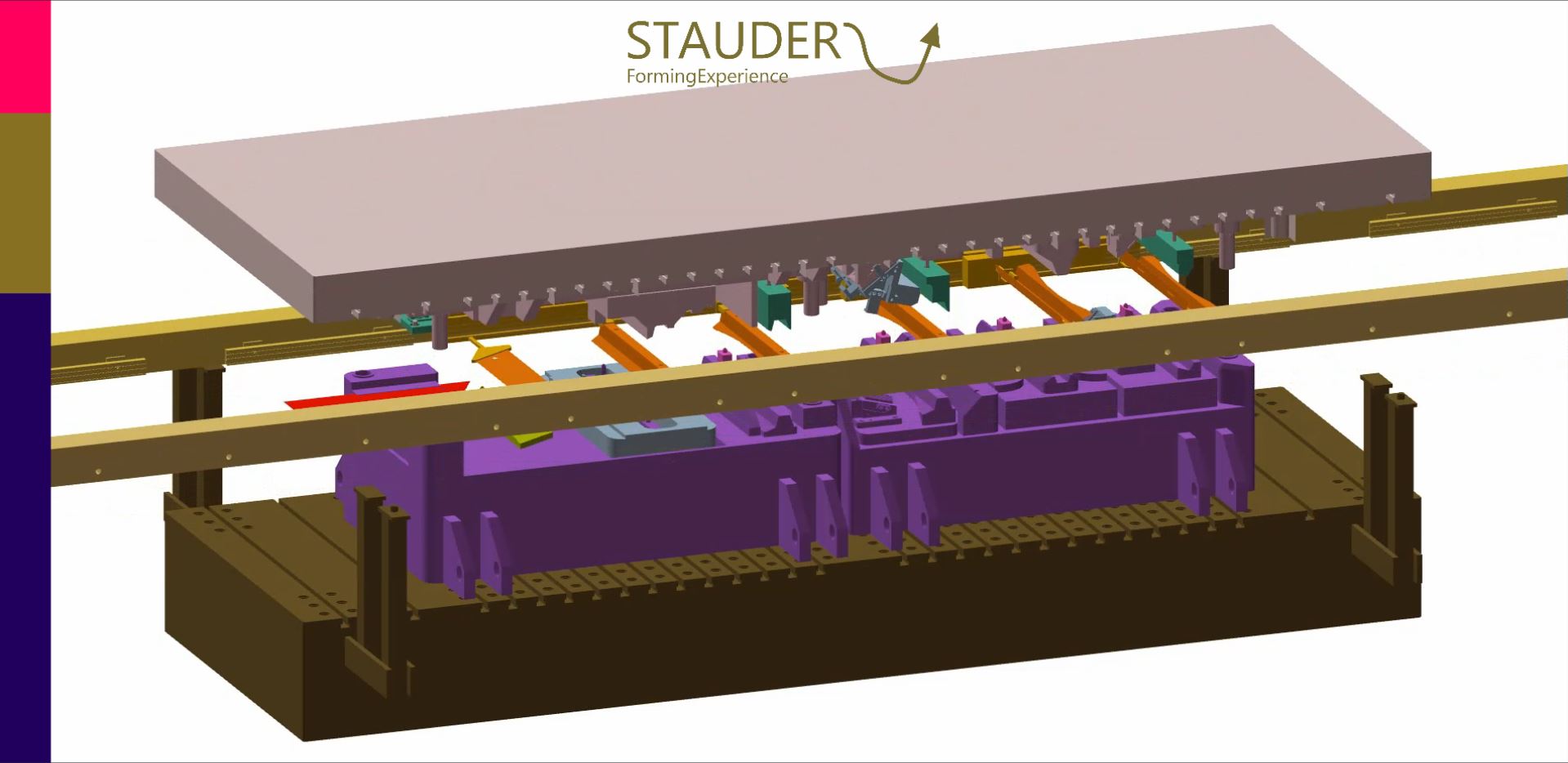

The use of kinematic simulation in the metal forming creates a better understanding of the processes in and on press through visualization. The great advantage is that the entire process can be tested offline and in advance of the existence of real machine or die.

To increase productivity on hot forming equipment, it is not enough to optimize the part transportation within the die clamping area. The entire part transfer process including the heating and feeding process must be simulated.

13. Mai 2021

One of the principles that drives me is "Simplicity is the soul of efficiency".

This sums up what kinematic virtual simulation of press and die movements is for. This 3D CAD data-based methodology is the key to accelerate die design times and minimize machine downtime. But best of all, the combined view of die design in the context of machine movements makes the potential output rate predictable and thus the design optimizable.

05. April 2020

We are receiving dramatic pictures and messages these days.

But isolated glimmers of hope - as is currently the case at the petrol pumps - delight the consumer. And I am sure that just as the sun rises again after every night, we will overcome this crisis together.

Would you like to know how you can save on training in sheet metal forming?

Webinars for press setters provide basic knowledge for the optimal parameters of servo presses and/or for 3D / 3axis transfers.

25. März 2020

Social distancing? Low order volumes? What about the health of the loved ones? …?

A resource that is very rare in normal times - time - has been made available in the production environment.

Webinars offer an ideal opportunity to increase the knowledge of your employees while respecting the present ban on human contact. Use the time that has become free during these days without further interruptions in production, without affecting shift schedules to increase future productivity.

21. November 2019

Whether you want to prepare yourself for the challenges that industry 4.0 / IoT or e.g. as a reaction to electromobility brings, there are many reasons why you want to recruit experts for your company. Providing know-how and expertise in new business fields or niche areas is always a challenge.

We also encounter these challenges in our everyday lives, even beyond the above-mentioned trendy and visionary directions.

03. November 2019

Blechexpo and Fabtech trades are just around the corner, and for me this is heralding the final phase of the working year. This is the time to regularly spend time planning and designing the new year. Residual budgets can be of great help in implementing corporate goals and promoting your own employees. To think about the new year in time offers a personal advantage in the new year and increases the anticipation of a merry Christmas.

28. März 2019

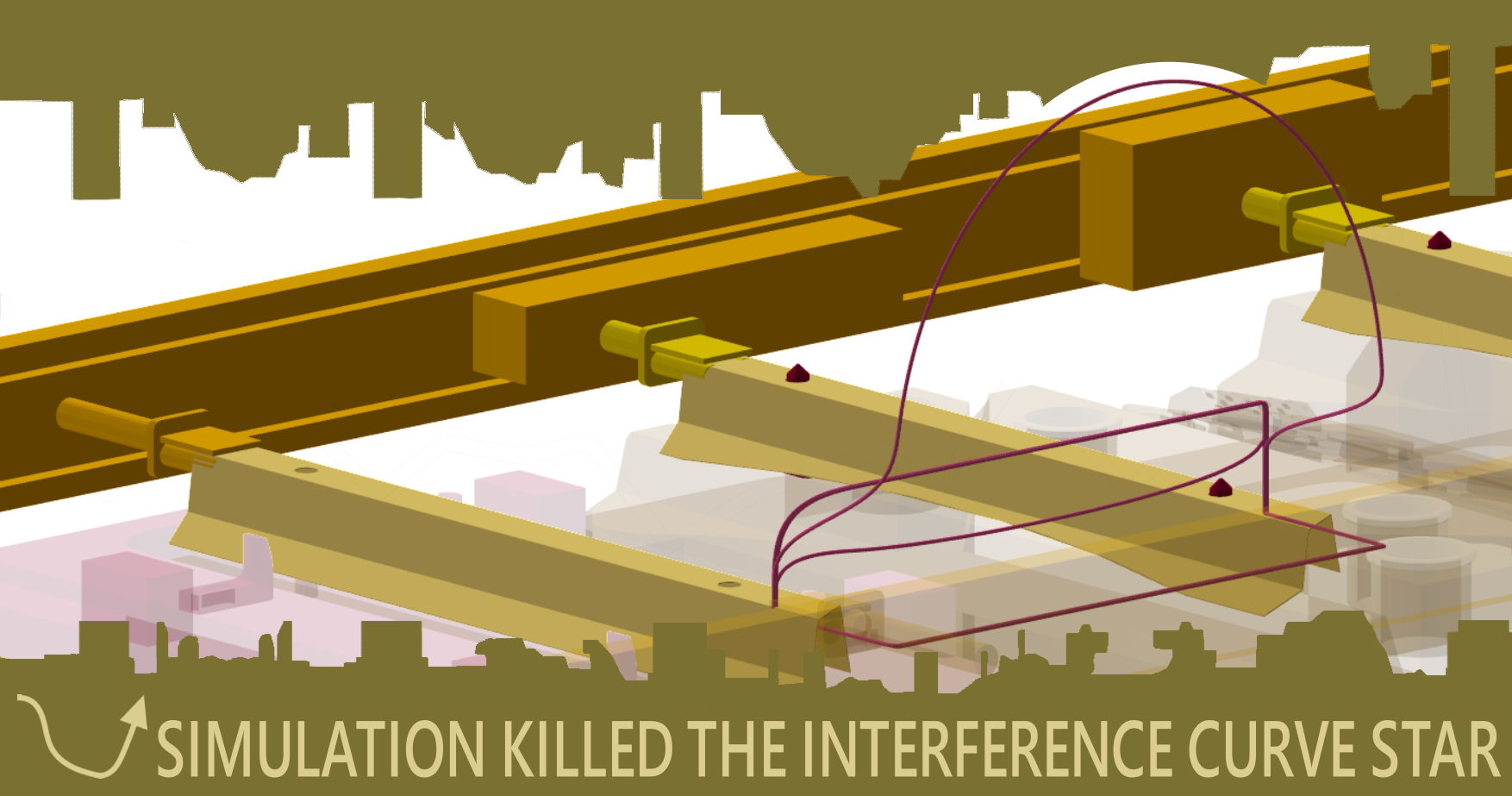

One would think that the correct application of clearance curves in the transfer tool design is not only an absolute must, but a matter of course.

A technically error-free and clear flow chart, whether classical with clearance curves or carried out based on a virtual flow simulation, enables the press to be operated at maximum output.

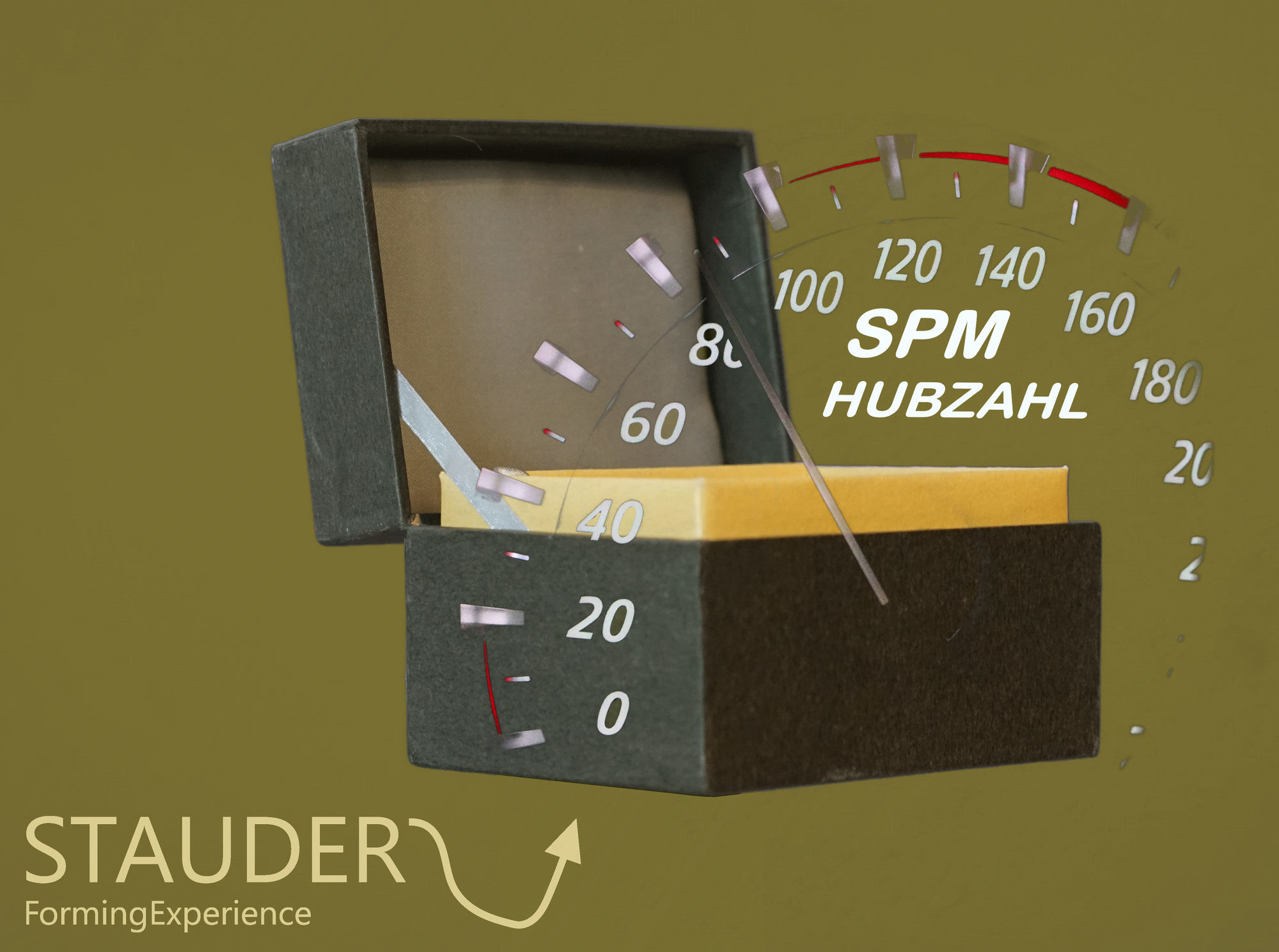

03. Februar 2019

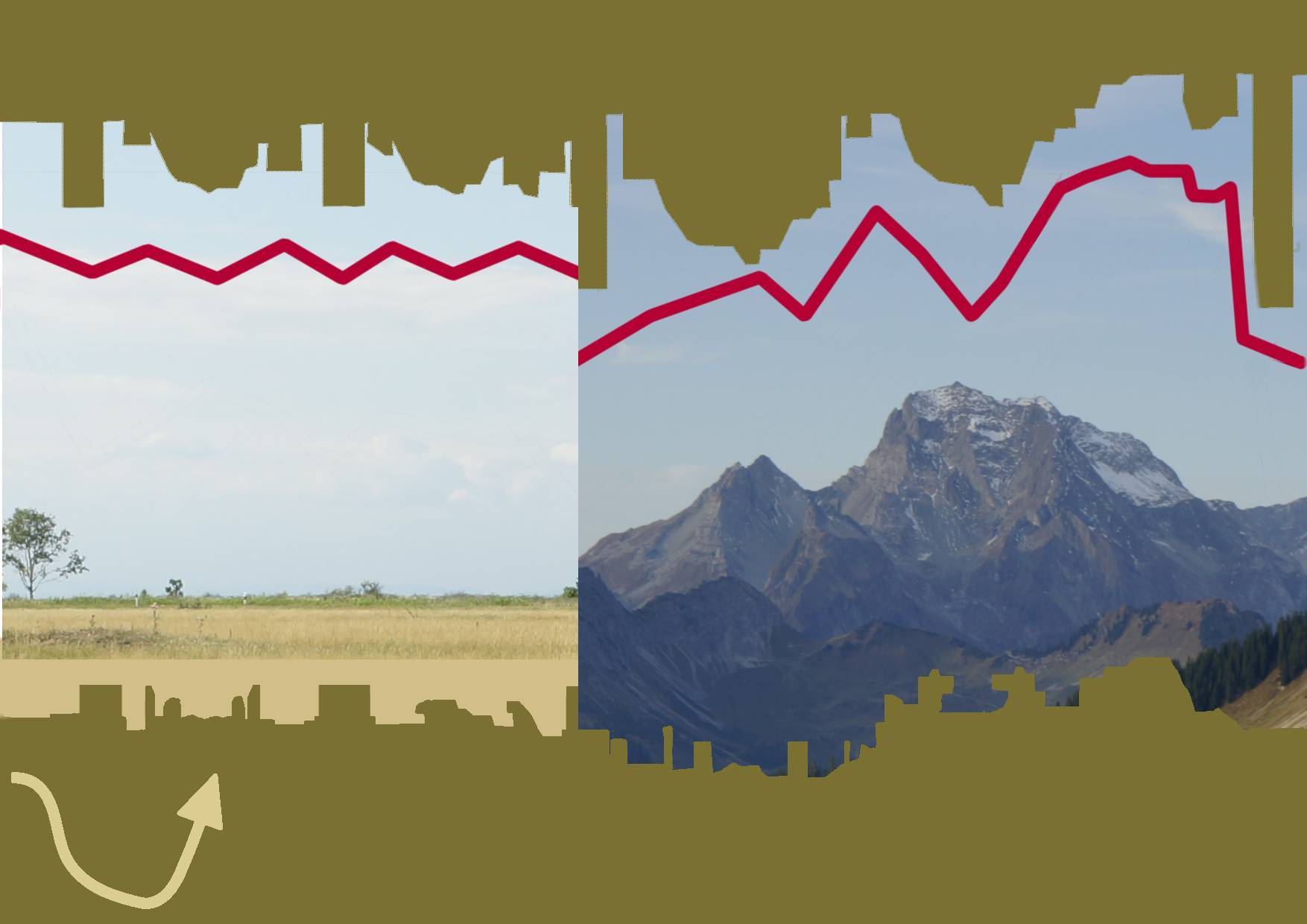

Identify the stroke rate potential of a tool design at a glance. Making the right decisions and actions when reviewing a tool design does not always take a lot of time.

Your significant benefit out of that is, you can set the course right in the early and initial stages of tool design!

18. Januar 2019

Increased productivity and efficiency in the press shop are largely dependent on the knowledge & experience of the setter personnel.

The experience of setting up perfect conditions on your forming equipement can be ordered as a service enabling you for:

- higher stroke rates

- optimum tool durability

- higher profit